Sika Marine | Environmental Considerations for Maritime and Shipping Products

There’s always a compromise between environmental considerations and costs when developing or working with products created for maritime and shipping markets. Unfortunately, for a very long time, sustainability has not been prioritized over durability and cost-effectiveness. This approach, however, has been changing due to recent global sustainability initiatives.

As Sika is a specialty chemical company with a leading position in development and production of aesthetic deck coverings, acoustic flooring solutions, bonding, sealing, and reinforcing products for many market segments including the maritime industry, we feel it is our obligation to the world to help the market step into a sustainable future by developing and implementing new technologies, which include our environmental principles, from the very beginning of the development phase. Sika’s mission is to convert the environmental compromise into a balance, where sustainability and durability are paramount and there is no need to sacrifice the quality or eco-friendliness. To help the shipbuilding industry to reduce CO2 emissions, Sika has developed an ultra-light weight floating floor solution that will reduce the weight by at least 24 kg/m2 compared to a traditional floating floor construction used nowadays in the shipbuilding industry. Different types of ships all have floating floors installed for acoustic comfort or as A-60 fire rated floor. Floating floors in larger areas are used onboard cruise ships, expedition ships, RoRo car ferries, passenger ferries, supply vessels, mega yachts, and research vessels, just to mention some ships where floating floors are used. By reducing the weight of the ship construction, we can help by minimizing the fuel and energy consumption and reducing the emission of CO2 in the building and supply chain.

In order to substantiate the above business case on weight savings, reduced fuel consumption and CO2-footprint, Sika has ordered an independent study from GSR Services on this data. The study compares two different Sikafloor Marine floating floor systems when used in a large cruise ship newbuilt construction. GSR Services GmbH compared the Sikafloor® Marine- Litosilo Steel, which has a total weight of 48.1 kg, to the Sikafloor Marine UL-FF 2.

1. FUEL SAVINGS MGO (MARINE GAS OIL) (GSR STUDY)

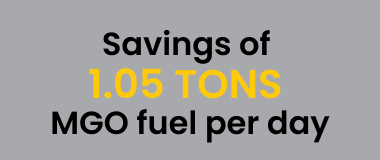

Comparing the installed power with related fuel consumption per sailing day results in a daily MGO consumption of approximately 257 tons with the conventional floating floor system. With the new floating floor system UL FF-2, a reduction of 0.41% equals savings of approximately 1.05 to of MGO fuel per day (or 383 tons/year – depending on sailing days).

Comparing the installed power with related fuel consumption per sailing day results in a daily MGO consumption of approximately 257 tons with the conventional floating floor system. With the new floating floor system UL FF-2, a reduction of 0.41% equals savings of approximately 1.05 to of MGO fuel per day (or 383 tons/year – depending on sailing days).

With a view on MGO prices of 1.100 $/t at the time of data collection, this corresponds to a daily saving of 1.158 $ (up to 422.670$/year – depending on sailing days).

2. FUEL SAVINGS LNG (GSR STUDY)

The specific fuel consumption including operational pumps for one full sailing day results in a daily LNG consumption of approximately 194, a reduction of 0.41% of installed power saves approx. 0.8 to of LNG per day (approx. 292 t/year – depending on sailing days). With a view on LNG fuel prices of 3000$/t at the time of data collection1, this corresponds to a daily saving of 2.389 $ (up to 871.985$/year – depending on sailing days). It is to be noted that LNG bunkers are available in different qualities mirrored in ‘lower heating value’ which has been taken into consideration for the calculation.

The specific fuel consumption including operational pumps for one full sailing day results in a daily LNG consumption of approximately 194, a reduction of 0.41% of installed power saves approx. 0.8 to of LNG per day (approx. 292 t/year – depending on sailing days). With a view on LNG fuel prices of 3000$/t at the time of data collection1, this corresponds to a daily saving of 2.389 $ (up to 871.985$/year – depending on sailing days). It is to be noted that LNG bunkers are available in different qualities mirrored in ‘lower heating value’ which has been taken into consideration for the calculation.

3. DAILY CO2 EMISSION REDUCTION MGO (GSR STUDY)

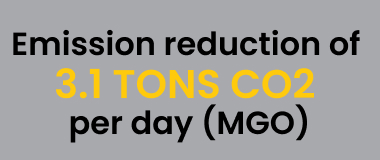

According to data from Helmholtz (Gemeinschaft deutscher Forschungszentren) 2, burning 1 liter of diesel produces 2.65 kg CO2. Taking MGO density into account (890 kg/m3), the reduced installed power corresponds to a daily emission reduction of approximately 3.1 to CO2 (or 1.132 to CO2/year – depending on sailing days).

According to data from Helmholtz (Gemeinschaft deutscher Forschungszentren) 2, burning 1 liter of diesel produces 2.65 kg CO2. Taking MGO density into account (890 kg/m3), the reduced installed power corresponds to a daily emission reduction of approximately 3.1 to CO2 (or 1.132 to CO2/year – depending on sailing days).

4. DAILY CO2 EMISSION REDUCTION LNG (GSR STUDY)

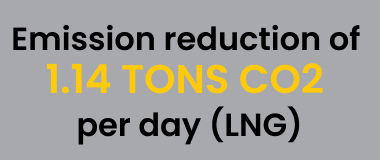

The converter tool3 of the ICBE (International Carbon Bank & Exchange) has been chosen to calculate the carbon dioxide emission saving for LNG used as fuel.The daily fuel saving of around 0.8 tons LNG and a density of 450 kg/m3 corresponds to a daily emission saving of approximately 1,14 to CO2 (or 416 to/year – depending on sailing days). Generally, it should be noted that using LNG as fuel results in an NOx reduction of approximately 80% whereas carbon dioxide emissions remain relatively similar for the different types of fuel as per the available literature on this subject.

The converter tool3 of the ICBE (International Carbon Bank & Exchange) has been chosen to calculate the carbon dioxide emission saving for LNG used as fuel.The daily fuel saving of around 0.8 tons LNG and a density of 450 kg/m3 corresponds to a daily emission saving of approximately 1,14 to CO2 (or 416 to/year – depending on sailing days). Generally, it should be noted that using LNG as fuel results in an NOx reduction of approximately 80% whereas carbon dioxide emissions remain relatively similar for the different types of fuel as per the available literature on this subject.

NOISE REDUCTION PERFORMANCE

In noise and vibration control, the most important tasks are the minimization of the excitation and of the propagation of sound in structures. Furthermore, the transfer from structure- borne sound into airborne sound – the vibration-induced radiation of sound – should be kept as low as possible. Therefore, at Denmark’s Tekniske Universitet (DTU), Sika has also performed sound tests with the combination of visco-elastic and the Sikafloor® Marine UL FF floating floor systems. The Sikafloor® Marine VEM190 and Sikafloor® Marine VEM-X viscoelastic systems are damping the structure-borne noise by transfer of vibration energy into heat caused by the friction between the constrained layer and steel deck with the visco-elastic layer causing that effect. The Sikafloor® Marine UL FF floating floor system which is in The vibration induced radiation of noise in the low frequency range up to 250 Hz will not be reduced/damped by the floating floor. Therefore, in specific areas, e.g., over the propulsion/propeller areas it’s necessary to apply the visco-elastic floor to dampen the propagation of structure borne noise. Other areas e.g., over the engine room, thruster compartments, HVAC, etc., the noise sources are transmitting noise into both structure-borne as well as airborne noise in the adjacent compartments and decks above. Here it’s necessary to install a combination visco-elastic and floating floor solution, shown below.

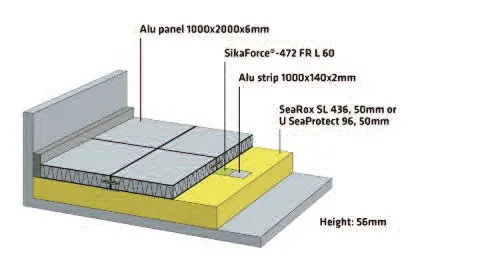

The Ultra-Light weight floating floor is built up by a layer of 50 mm mineral wool slaps. Strips are placed on top of the mineral wool in a pattern under the joints of the ultra-light weight panels and bonded with SikaForce®-472 adhesive.

The panels are assembled by a tongue and groove system and on top, a watertight levelling can be installed with Sikafloor® Marine-570 or -590.

INSTALLATION

The installation process will be easier compared to the installation process of a full steel floating floor system. As steel plates are heavy and come in a size of 1 x 2 mtr. the onboarding process and transportation to and on the ship takes a lot of time. With the light weight aluminum panels, multiple panels can be transported on the ship at the same time. In addition, a synthetic watertight and flexible levelling membrane can be applied with Sikafloor®Marine-570 and/or -590.

For addition application details please refer to the Additional Product Information of Sikafloor®Marine Ultra-light floating floor system.

APPLICATION AREAS AND ADVANTAGES

Sikafloor® Marine ULFF is suitable for all interior installations in passenger, crew cabin areas and public areas. Only for areas where an extremely heavy load is expected, the ship designers could consider traditional Sikafloor® Marine floating floor systems.

ADVANTAGES FOR THE OWNERS, DESIGNERS, SHIPBUILDERS, WORKERS, AND ENVIRONMENT

- Extreme / Significant weight savings

- Fast ROI

- High savings in energy and fuel consumption during operations

- Savings in the structural construction

- A60 fire rated floor

- Acoustic performance fully documented

- Including documented Visco Elastic solution

- Good dynamic behavior

- No VOC

- No EH&S issues

- Easy processing and fast to install, reducing labor costs and time on site

- Reduced transportation costs

- 98% recyclable flooring panels

- Good corrosion resistance

- Waterproof, flexible membrane layer

- Certification according to IMO//SOLAS, EC-Type examination Certificate, Wheelmark MED-B and -D

- US Coast Guard approved

SUMMARY

Sika’s innovative new ultra-light weight floating floor solution paves the way for a sustainable future in the shipbuilding industry. Aimed at minimizing fuel and energy consumption and reducing CO2 in the building and supply chain, our solutions offers several advantages over traditional flooring solutions.

We remain at the forefront of advanced flooring systems and continue to deliver on our customers’ requirements.

More information on SIKA’s sustainability policy:

https://www.sika.com/en/about-us/sustainability/sika-sustainabilitystrategy.html

Contact

Corrado Sallustio, Corporate Market Field Manager Marine

Email: sallustio.corrado@it.sika.com

www.sika.com/marine