Putting A Seal On Leaking Wrecks

When the flow of oil escaping from a sinking ship has stopped the problem may still be only partly solved. The huge costs to the environment and to the polluter and its insurers do not necessarily end just because the containment booms and the clean-up teams have gone.

A wreck on the seabed may still contain a significant volume of oil and although it may be hoped that it is securely trapped within the vessel’s cargo and fuel tanks it remains as a threat. Wave action, movement of the wreck or its deterioration can result in the intermittent release of hydrocarbons into the water. This can mean that just when a coastal community has started to return to normal following an incident a new release of hydrocarbons -or any other liquid pollutant for that matter – can occur. This is a very real liability that can arise long after the incident when the pressure inside the damaged bunker or cargo tanks has become equalised. Although the initial outpouring has stopped, any large volumes of hydrocarbons trapped within the vessel may consequently become discharged intermittently.

While no two casualties are the same, the use of magnetic or flexible patches can often provide the most cost effective insurance against the risk of further leakage and the recurring damage and costs that can result. Miko Marine AS of Oslo is well known for its range of flexible magnetic patches that have saved the world’s coasts from pollution on several occasions. They are regularly deployed to seal hull damage to a vessel and prevent it from sinking and they are now considered so valuable that emergency packs of them are carried by all Norwegian coastguard vessels so that they are immediately available for use when helping in an emergency.

The ease with which magnetic patches can be applied also makes them particularly suitable for minimising the risk of pollution from a sunken vessel. The only alternative to their use may involve the huge cost of welding a patch into place on a wreck. This can be a difficult and dangerous task for divers and may take several days if the damage is substantial or complicated. If the wreck is lying in waters that are too deep for divers, remotely operated vehicles (ROVs) offer the only alternative yet these may be incapable of performing any but the simplest and most straightforward of welding tasks. Because the costs and risks of such work are so great insurance companies may instead prefer to avoid it and simply make a fresh round of compensation if the need arises. Unfortunately this does not help the communities that suffer the consequences of any leak. Compensation will be seen as a poor substitute for the pollution that should not have occurred in the first place.

Although Miko patches are sometimes likened to a large, flexible fridge magnet, magnetism is usually all that they have in common. Several years of research were needed to develop a patch capable of achieving a powerful bond through what may be many layers of paint or corrosion between it and the metal of the ship. This has been achieved by mixing rare earth particles with an exceptionally strong blend of Nitrile rubber. Because a finished patch will weigh 10 kgs per square metre an additional layer of material is laminated onto it to provide buoyancy. With lifting lugs also fixed to the patch during manufacture it can be easily manoeuvred into position under water by divers or by an ROV when working in deep water. Once in place the powerful magnetic bond can, if desired, be reinforced by additional magnets to create a dependable water tight seal to eliminate the danger of further oil leakage or even to enable interior compartments to be pumped dry.

When damage to the vessel leaves an uneven surface it may not be possible to achieve an effective seal with Miko magnetic patches alone. If this happens the company has a range of “hat shaped” patches that can be used with equal effect. They are described as “hat-shaped” due to their design as a shallow bag with a brim and are manufactured from a high strength fabric that combines aramid with polyester reinforced PVC. The bag is able to accommodate any irregular or protruding damage and is held securely against the hull beneath flexible aluminium strips that are stapled into place by divers to create an effective and durable seal.

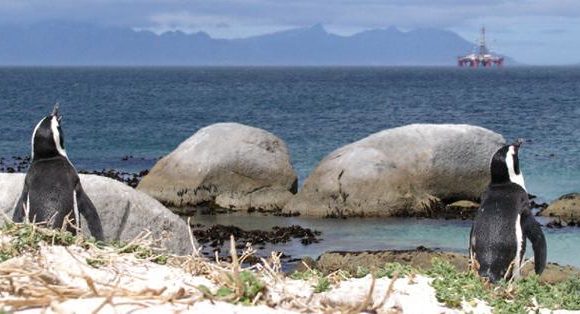

Regardless of whether a magnetic or “hat-shaped” patch is considered the most appropriate, they both offer a viable means of eliminating the risk of further pollution. Their availability now enables coastal communities to protect themselves by demanding that they are used on wrecks to ensure that they do not persist as a long term threat to their environment.